Tanatone

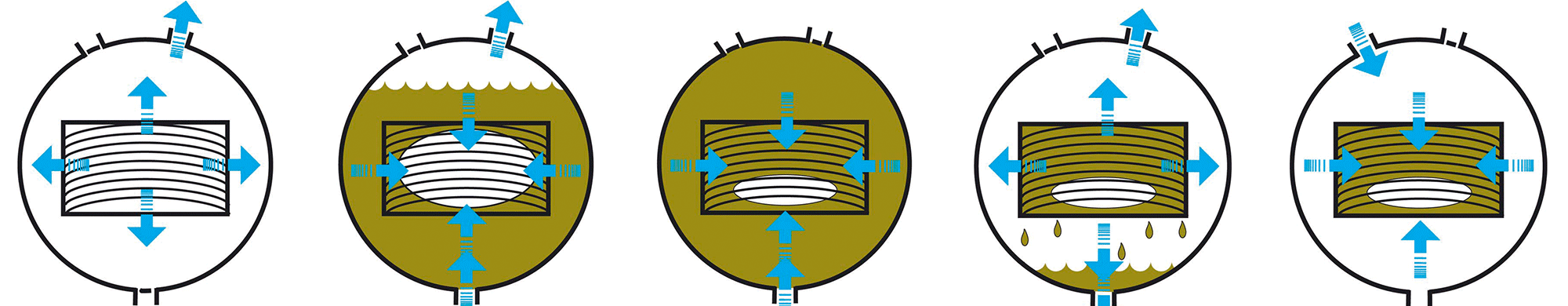

- Timber loaded into treatment vessel. Initial vacuum applied and the timber cells are evacuated of air. Vacuum held.

- Cylinder flooded under vacuum with TANALITH E wood preservative, with TANATONE brown colourant, if required.

- Hydraulic pressure applied, forcing the preservative deep into the structure of the timber.

- Final vacuum extracts excess preservative solution, which is pumped back to storage.

- Low pressure inside the timber draws in surface solution when vented to atmosphere. Treated timber is left to dry.

End Grain Preservatives

When installing preservative treated timbers it is important that any cuts or notches are retreated with a suitable, brush-on end grain preservative to maintain the total integrity of the preservative protection. James E Smith offers both green and brown coloured end grain preservatives from stock for TANALITH E and TANATONE treated timbers.

Read the Specifiers Guide to High Press Timber Treatment here

View the Tanalith™ and Tanatone™ Treated Timber User Guide here